These flame brazing units streamlines operation, requiring only two steps: igniting the torch and hanging it on the hanger post-task.

- Efficient Ignition Our torches feature spark igniters for ignition, ensuring gas savings and eliminating the need for manual adjustments.

- Emergency Safety Measures In emergencies like earthquakes or accidents, gas release from the torch stops within 2.0 seconds. The "full interlock" system ensures that even if power is cut off and restored, the electromagnetic valve remains locked, preventing gas release.

- Reliable Operation With no pilot flame, there's no risk of nozzle clogging. Spark-based ignition eliminates the possibility of extinguishing due to airflow from fans or spot coolers.

- Enhanced Ignition Stainless steel body, ensures durability. Plus, the ignition part's mounting orientation can be changed by 90 degrees, making ignition easier. Experience simplified, safe, and efficient flame brazing with our innovative system.

Our DE SAVER (N-500) Gas Saver revolutionizes flame brazing operations with its solenoid control and automatic spark igniter, eliminating the need for a pilot flame. By removing the pilot flame, this product maximizes cost reduction, safety, and ease of use.

Key features include:

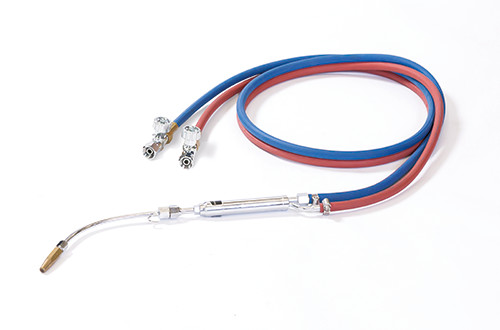

Optional Valveless Torch: For added convenience and versatility, choose the valveless torch option, simplifying torch operation and maintenance.

-d3d94.w640.png)

Our DE SAVER (N-500P) Gas Saver incorporates an additional Nitrogen circuit. This allows operators to perform Nitrogen purges before and/or after brazing. This is an important step in the HVAC industry that involves flowing dry nitrogen through refrigeration and AC line sets before and during brazing to prevent oxidation. Nitrogen is inert and displaces oxygen, which can cause black oxide. Over time, the black oxide forms scale and flakes off, which can become trapped in the valves or metering orifice and cause premature failure.

Optional Valveless Torch: For added convenience and versatility, choose the valveless torch option, simplifying torch operation and maintenance.

FOR MORE INFORMATION, DOWNLOAD OUR PAMPHLET

Download N-Series Pamphlet

Experience a game-changer in gas management with our innovative Gas Saver. It's designed to enhance safety, reduce costs, and streamline work management for manual brazing tasks.

Key features include:

- Energy-Saving: Spark igniter type eliminates the need for a pilot flame, ensuring efficient operation.

- Safety: Automatic gas flow stoppage if the torch dislodges from the hanger, prioritizing workspace safety.

- Functionality: Customizable gas and oxygen flow rate control.

- Dual Flame: Two separate gas and oxygen flow rate mix settings with instant changeover via foot switch.

- Process Control: Digital gas and oxygen flow rate displays aid in engineering process management.

-

- Process Stability: Repeatability and process control enable improved quality for operators of varying skill levels.

FOR MORE INFORMATION, DOWNLOAD OUR PAMPHLET

Download DE-2500 Pamphlet

Our innovative approach to torch design eliminates the need for valves, resulting in significant weight reduction and a more comfortable working environment for brazing operators.

・Lightweight Design by removing the valves, our torches are lighter, reducing operator fatigue and enhancing maneuverability during brazing tasks.

・Improved Comfort Operators can enjoy a more ergonomic experience without the bulk of traditional valve-equipped torches, leading to increased efficiency and productivity.

Upgrade your brazing process with our innovative fluxing system. A main Vapour Tank, reserve upper tank, and a Controller, ensure a stable level of liquid flux in the main vapor tank, and a stable volume of vapour flux in the brazing environment.

Efficient Flux Management Our system optimizes flux usage, reducing waste and improving efficiency.

Adaptive Performance In low ambient temperature environments, warm water can be placed in the unit base for optimal fluxing performance (high-water type).

Enhanced Productivity With a removable reserve upper tank, experience uninterrupted brazing operations with our system. Enjoy increased productivity and consistency.

The image shown depicts the high-water type for visual clarity.

FOR MORE INFORMATION, DOWNLOAD OUR PAMPHLET

Download V. Auto Tank Pamphlet-d3d94.jpg)

Experience effortless and consistent wire volume dispensing with our Pneumatic Wire Feeder. Its pneumatic drive mechanism ensures smooth, consistent operation, optimizing your manual brazing process.

Effortless Control, Enhanced Efficiency With intuitive push-button operation, a fixed volume/length of filler metal is dispensed to the braze joint, reducing waste while providing additional process control.

Durable Ceramic Tip Equipped with a premium ceramic tip, our wire feeder ensures exceptional durability and wear resistance, guaranteeing consistent performance even in demanding conditions.