Customizable Specifications With customizable specifications, our units offer versatility to meet the unique requirements of your brazing tasks. Perform a range of operations including burner front-back, burner up-down, two-stage heating, and oscillation, ensuring precise control and optimal brazing conditions tailored to your specific needs.

Precision and Control Experience precise temperature control and efficient heating with our Heating Units, ensuring consistent and reliable results in your brazing operations.

Customizable Specifications

With customizable specifications, our units offer versatility to meet the unique requirements of your brazing tasks. Execute a range of operations including burner front-back, burner up-down, two-stage heating, and oscillation, ensuring optimal performance tailored to your specific needs.

Precision and Efficiency

Experience precise and efficient heating with our Pre-Heating Units, ensuring consistent and reliable results in your brazing operations.

Precision Gas Flow Measurement

Utilizing mass flow measurement, our system accurately measures the number of molecules rather than the volume of gas. This design renders it resistant to pressure fluctuations, guaranteeing consistent and reliable performance in various operating conditions.

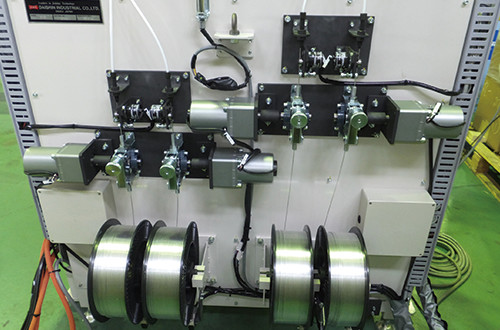

Customizable Wire Control

With encoder control, you have the flexibility to adjust both the amount of wire supplied and the feeding speed, ensuring precise control over your welding process. Experience unparalleled accuracy and efficiency with our wire feeding unit.

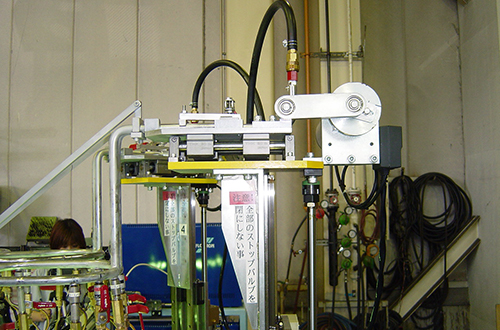

Our Burner Oscillation Unit ensures uniform heating and delicate brazing by oscillating the burner. Achieve precise control over your brazing process with adjustable oscillation speed, controlled by the volume of the oscillation motor.

Versatile Oscillation Patterns

Experience both front-back and left-right oscillation capabilities, providing comprehensive coverage and ensuring even heating across the workpiece. Elevate your brazing operations with our Burner Oscillation Unit for consistent and high-quality results.

With two wire cylinders installed on each side, our feeder unit guarantees an ample and continuous supply of wire, maximizing productivity and minimizing interruptions.

Flexible Wire Nozzles

Equipped with wire nozzles controlled by air cylinders, our unit offers the versatility of both forward and backward wire supply, allowing for precise positioning and control. The number of wire nozzles can be adjusted according to the volume of your workpiece, ensuring optimal performance and efficiency.

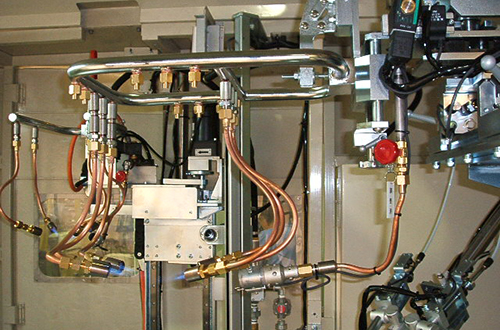

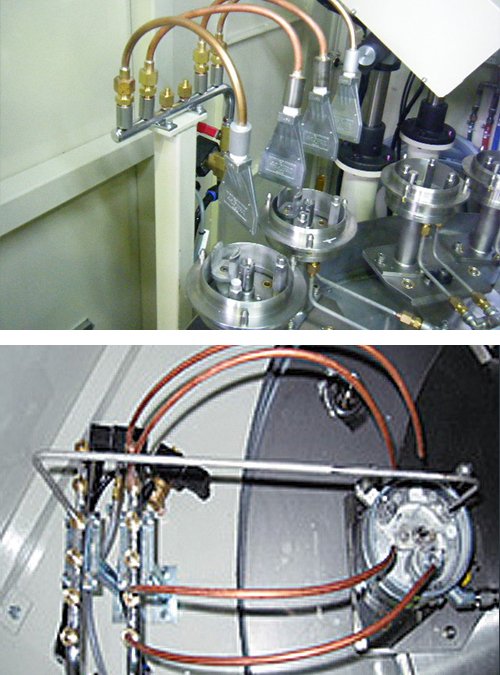

Our Gas Box Unit is the central control hub for managing gas and oxygen (air) supply to the heating burner and preheating burner in your brazing system.

Pressure Monitoring and Safety

Equipped with pressure switches in the gas and oxygen (air) circuits, our unit ensures safety by monitoring pressure levels. In the event of abnormal conditions such as pressure drops, a buzzer alerts operators, allowing for timely intervention. The pressure switches feature numerical displays for easy monitoring and troubleshooting.

Efficient Gas and Oxygen Control With precise control over gas and oxygen (air) supply, our Gas Box Unit optimizes the brazing process, ensuring consistent and reliable performance.

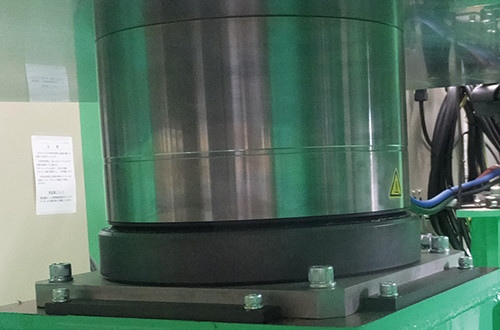

Our Rotary Unit features CKD's Absodex technology, ensuring unparalleled performance and precision in rotation positioning.

Key Benefits of Absodex:

High-Precision Rotation Positioning: Achieve precise positioning with accuracy and consistency, vital for demanding applications.

High Torque: Enjoy robust performance with high torque capabilities, providing the power needed for efficient operation.

Absolute Position Detection: With resolver-based absolute position detection, eliminate the need for origin returns, streamlining operations and saving valuable time.

Smooth Drive: Experience smooth and reliable operation, thanks to the optimal cam acceleration curve, ensuring seamless movement and reduced wear and tear.

Flexible Cooling Options

Depending on the material and requirements of the workpiece, you can choose between air cooling, water cooling, or a combination of both. This flexibility ensures optimal cooling and helps maintain the integrity of the brazed joints.

Customizable Cooling Sequences

For certain materials, such as those with high thermal conductivity, a combination of air cooling followed by water cooling may be necessary to achieve the desired temperature reduction. Our device allows for customizable cooling sequences to meet your exact specifications.

Experience enhanced post-brazing cooling with our Water Cooling / Air Cooling Device, providing versatility and reliability for your brazing operations.

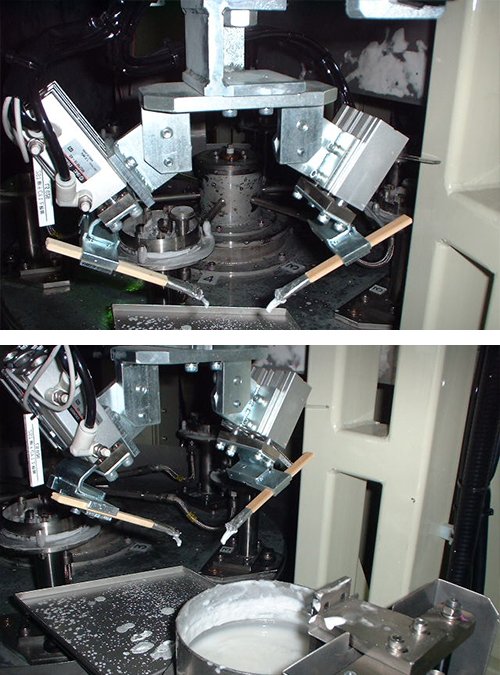

Our Flux Application Unit automates the flux application process before brazing, enhancing efficiency and reducing operator burden in table-type brazing machines.

Automated Flux Application

Installed before the brazing station, this unit picks up paste flux with a brush attached to the tip as the workpiece arrives. It then applies the flux seamlessly as the workpiece moves toward the brazing station, ensuring uniform coverage and consistent application.

Benefits of Automation

By automating the flux application process, our unit significantly reduces cycle time and alleviates the need for manual intervention, improving overall productivity and streamlining operations.

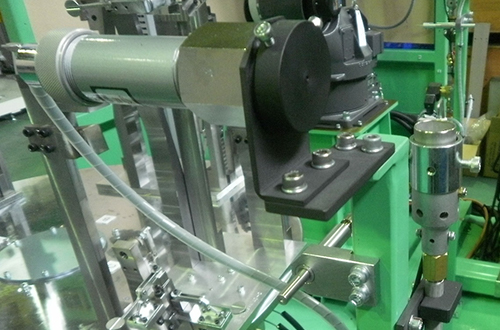

Our innovative unit automates the ignition process of the burner, ensuring seamless operation in robotic brazing machines or porous burner setups.

Automatic Ignition

With automatic ignition capabilities, our unit eliminates the need for manual intervention, streamlining the startup process and reducing downtime.

Flame Out Detection

In addition to ignition, our unit features flame out detection functionality. This ensures that the burner remains operational during brazing processes, providing peace of mind and preventing disruptions.