MODEL HS (Horizontal Type)

The Model HS is engineered with efficiency and versatility in mind, featuring one set of work-holding fixtures and heating brazing units. Its straightforward mechanical structure makes it ideal for the initial stages of automation or scenarios with lower production quantities.

Two Available Types:

HS-II Type: This variant boasts two fixtures sliding on one heating device, optimizing space and enhancing operational efficiency.

HW Type: In this configuration, heating devices are positioned for each of the two fixtures, offering flexibility and adaptability to varying production needs.

Elevate your brazing operations with the Model HS Automated Brazing System, offering precision, reliability, and performance tailored to your specific requirements.

- ・Single Station Machine with Large HMI Touch Panel

- ・Flotron Intelligent Gas Controller

- ・Fully Customizable Fixture and Burner Design

- ・Stationary Fixture at Operator Position

- ・Burner unit (and wire feeder, if applicable) advances to the fixture for brazing and returns to home position at the end of each cycle

- ・Ideal for introductory use or lower-volume applications

- ・Option to increase throughput by adding a second set of fixture and burner unit (Model HW)

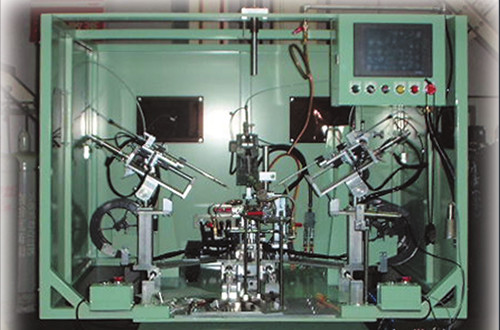

MODEL HS-T (Horizontal Type w/ Flip Table)

The Model HS-T, Horizontal Type with Flip Table, offers innovative solutions for efficient brazing operations. Featuring two fixtures arranged facing each other on a 180-degree flip table, this setup maximizes productivity by minimizing time loss during the process.

Streamlined Workflow - While one fixture securely holds the workpiece, the other undergoes heating for brazing, ensuring continuous operation and optimal efficiency.

Ease of Transition - Transitioning to a different model is simplified with the Model HS-T. By pre-installing an additional fixture, a seamless shift to a different model requires just a 90-degree rotation of the flip table, saving time and effort.

Upgrade your brazing operations with the Model HS-T Automated Brazing System, offering precision, reliability, and efficiency for your production needs.

- Two-station machine with 180° rotating table

- Large HMI Touch Panel for easy operation

- Flotron Intelligent Gas Controller for precise gas mix ratio and delivery

- Fully customizable fixture and burner design

- Operator loads/unloads parts while brazing occurs on the other side of the table

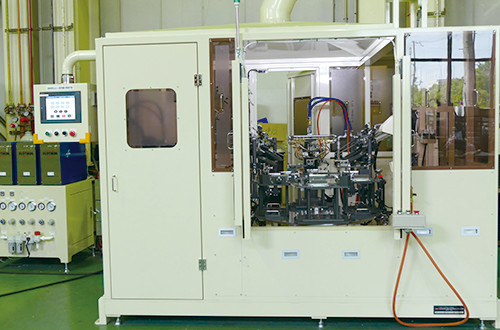

MODEL T (Table Type)

The Model T, in its Table Type configuration, stands as the cornerstone of mass production, offering unparalleled efficiency and automation capabilities. With 2 to 16 stations of indexing (absolute index), it caters to high-volume production demands with ease.

Comprehensive Automation - This configuration enables full automation across the brazing process, encompassing parts supply, flux application, preheating, heating brazing, cooling, and extraction. Each station operates simultaneously, ensuring seamless coordination and maximizing throughput.

Optimized Cycle Times - Even in processes with numerous steps, the Model T excels in efficiency. Its simultaneous operation capability ensures relatively short cycle times, enhancing productivity and overall performance.

Upgrade your production capabilities with the Model T Automated Brazing System, delivering precision, reliability, and efficiency for your mass production needs.

- ・Indexing Table Type (2-16 station capacity)

- ・CKD Absodex table rotation unit

- ・Large HMI Touch Panel for easy operation

- ・Flotron Intelligent Gas Controller for precise gas control

- ・Fully customizable fixture and burner design

- ・Post-brazing air and/or water cooling of parts

- ・Table indexes by cycle time

- ・Operator loads/unloads parts while other fixtures move to each station on the index table

- ・Ideal for high volume production

MODEL C (Conveyor Type)

The Model C is a specialized machine designed specifically for brazing return bends of heat exchangers, showcasing exceptional capabilities in mass production of uniformly brazed products.

Streamlined Production - Workpieces flow seamlessly between one or two pairs of burners on a conveyor at a constant speed, undergoing brazing as they pass through. This continuous flow ensures efficient and consistent production.

Customizable Setup - Setup changes for the width and height of the burners can be easily made to accommodate different workpiece dimensions, providing flexibility and adaptability to varying production requirements.

Elevate your mass production capabilities with the Model C Conveyor Type Automated Brazing System, delivering precision, reliability, and efficiency for your specialized brazing needs.

- Conveyor type brazing machine

- Used for return brazing to hear exchanger hairpins

- Bottom support slat, chain drive top tube sheet support, bottom support, palletized designs, etc. available

- Large HMI Touch Panel for easy operation

- Flotron Intelligent Gas Controller (for full control of combustion gas mix ration and delivery)

- Fully customizable fixture and burner design

- Parts are loaded either manually or automatically on the conveyor and pass through the machine for brazing. All braze settings are customizable and stored in the PLC, accessible via the HMI for quick and easy changeover

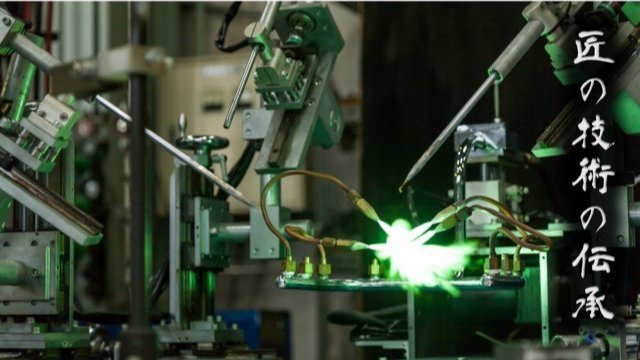

The Model R utilizes a 6-axis articulated robot to offer unparalleled flexibility in brazing a wide range of workpieces.

Versatile Workpiece Compatibility - With the ability to position jigs 60 to 90 degrees apart from the robot's base point, the Model R can accommodate various types of parts, ensuring versatility in brazing operations.

Adaptable Brazing Posture - Incorporating a flipping mechanism into the jigs allows for easy adjustment of the brazing posture, enhancing adaptability and precision in brazing tasks.

Small-Batch Production Capabilities - By exchanging the jigs, the Model R can seamlessly transition to accommodate small-batch production of various products, providing flexibility and efficiency in manufacturing processes.

Experience the ultimate in versatility and efficiency with the Model R Robot Type Automated Brazing System, delivering precision and reliability for a wide range of brazing applications.

- ・Robotic brazing machine with the robot carrying burner manifold (wire feeder and Vapour flux nozzles)

- ・Highly versatile system for brazing multiple joints on a single workpiece or single joints on a workpiece with complex or difficult braze joint orientation

- ・Automated fixture positioning can synchronize with robot positioning

- ・Large HMI Touch Panel for easy operation

- ・Flotron Intelligent Gas Controller for precise gas control

- ・Fully customizable fixture and burner design

- ・Post-brazing air and cooling of parts

- ・Parts are loaded into the fixture, brazed by the robot, and removed from the fixture at the end of the cycle

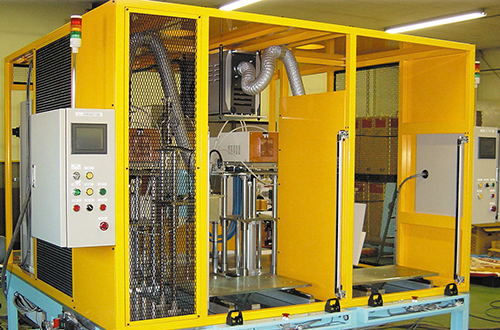

MODEL I (Induction Type)

The Model I harnesses the power of high-frequency induction heating to enable rapid and uniform localized brazing with ease.

Efficient Induction Heating- With high-frequency induction heating technology, achieving quick and uniform localized brazing is effortless, ensuring precise and consistent results.

Intuitive Control Panel - Featuring a user-friendly control panel with a touch screen interface, operators can easily switch between models, set timers, control individual operations for each model, and monitor abnormal conditions, enhancing efficiency and ease of operation.

Upgrade your brazing processes with the Model I Induction Type Automated Brazing System, delivering fast, uniform, and precise brazing for a wide range of applications.

- Induction brazing machine utilizing high-frequency induction coil for brazing parts

- Large HMI Touch Panel for easy operation

- Equipped with high frequency oscillator and current transformer for precise control

- Custom induction heating coil designed for specific applications

- Parts are loaded into the fixture, and the heating coil shifts to the heating position around the part for brazing