BRAZING FUNDAMENTALS

Brazing is a metal-joining process wherein two or more metals are bonded together by melting and flowing a filler metal into the joint. The filler metal typically has a lower melting point than the workpieces. Unlike welding, brazing does not melt the base metals, ensuring that their mechanical properties and dimensions remain intact.

Key Concept

- Filler Metal: The choice of filler metal is crucial and depends on the metals being joined, the required joint strength, and the operational environment. Common filler metals include aluminum-silicon, copper, silver, and nickel-based alloys.

- Flux: A chemical cleaning agent called flux is often used to prevent oxidation and to facilitate the flow of filler metal by cleaning the metal surfaces. Flux can be applied in paste, liquid, or powder form.

- Joint Clearance: The gap between the surfaces to be joined is critical for capillary action, which draws the molten filler metal into the joint. Optimal joint clearances range from 0.05 to 0.20 mm, depending on the metals and filler material used.

- Heat Source: Heat can be applied through various methods such as torch, furnace, induction, or resistance heating. The selected method depends on the size and complexity of the assembly, the required production volume, and the specific requirements of the joint.

- Capillary Action: This is the driving force in brazing, where the molten filler metal is drawn into the joint gap by capillary action. Proper joint design and adequate clearance are essential for effective capillary action.

- Temperature Control: Maintaining precise control over the heating process is crucial. The temperature must be sufficient to melt the filler metal but not so high as to damage the base metals.

Steps in the Brazing Process

- Cleaning: Remove contaminants from the surfaces to be joined.

- Assembly: Align and secure the parts to maintain proper clearance.

- Flux Application: Apply flux to the joint area.

- Heating: Heat the joint uniformly until the filler metal melts and flows into the joint.

- Cooling: Allow the joint to cool naturally to solidify the filler metal.

- Post-Cleaning: Remove any flux residues from the assembly.

AUTOMATION OF THE BRAZING PROCESS

The automation of brazing processes can significantly enhance consistency, productivity, and quality, particularly in high-volume manufacturing settings.

Key Elements of Automation

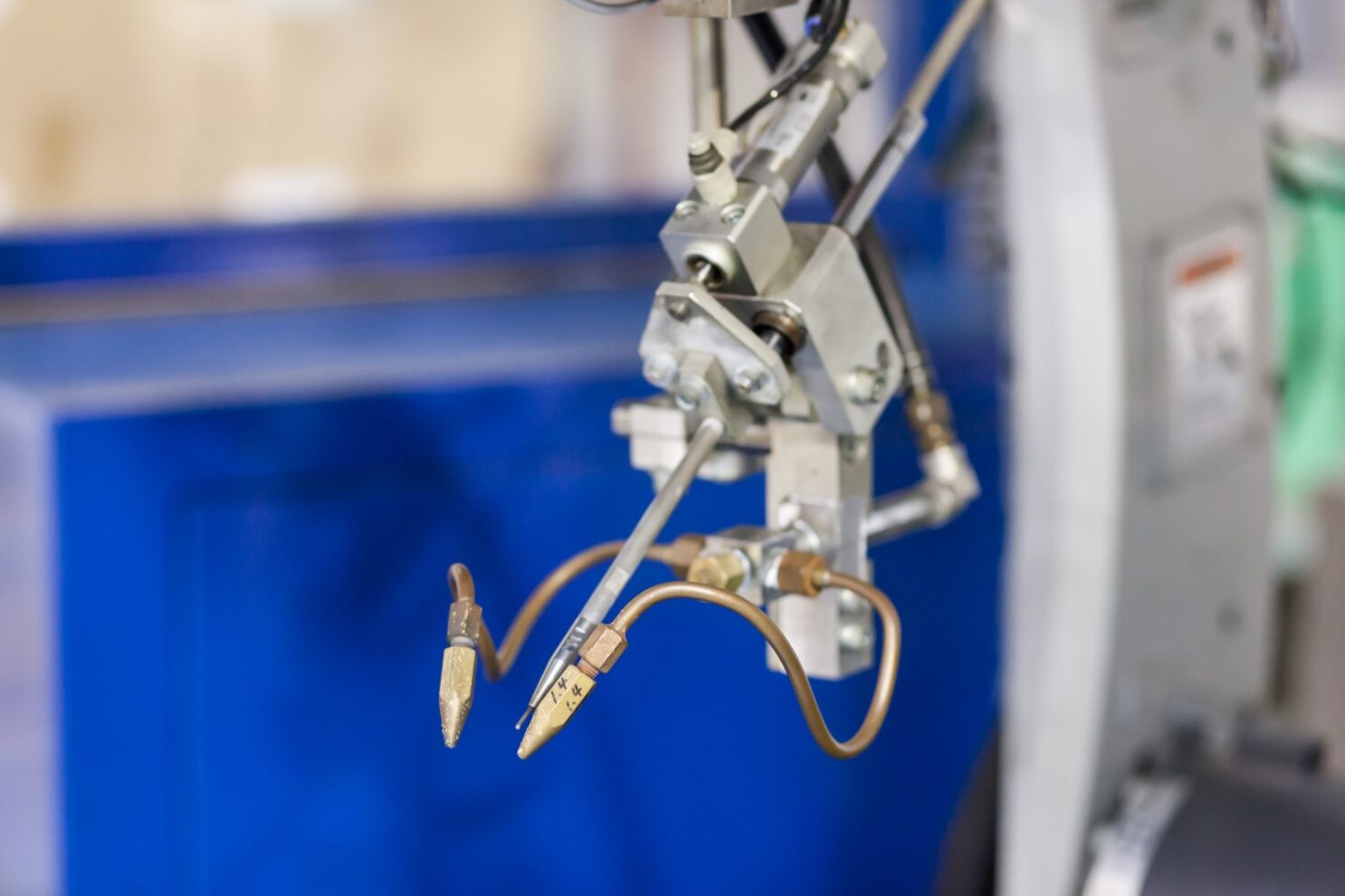

- Robotic Systems: Industrial robots can handle precise positioning, consistent application of filler materials, and uniform heating. Robots are ideal for repetitive tasks and can work in hazardous environments, reducing human exposure to risks.

- Induction Heating: Automated systems often use induction heating due to its efficiency and precision. Induction heating provides uniform and controlled heating, which is essential for high-quality brazed joints.

- Control Systems: Advanced control systems monitor and adjust parameters such as temperature, time, and flux application in real-time. This ensures consistent quality and reduces the likelihood of defects.

- Vision Systems: Integrated vision systems can inspect joint preparation, alignment, and quality, ensuring that only properly assembled parts proceed through the process. These systems enhance accuracy and reduce scrap rates.

- Material Handling: Automated material handling systems, such as conveyors and robotic arms, manage the movement of parts through the brazing process, increasing efficiency and throughput.

Benefits of Automation

- Consistency and Quality: Automation reduces human error, ensuring that each joint is produced to the same high standard.

- Increased Productivity: Automated systems can operate continuously, significantly increasing output.

- Reduced Labor Costs: Automation reduces the need for skilled labor, which can be costly and difficult to find.

- Enhanced Safety: By removing human operators from potentially dangerous environments, automation enhances workplace safety.

- Data Collection and Analysis: Automated systems can collect data on various parameters of the brazing process, enabling continuous improvement and optimization.

APPLICATIONS

Automated brazing is widely used in industries such as automotive, aerospace, HVAC, electronics, and medical devices, where high precision and reliability are paramount. For example, in the automotive industry, automated brazing is used to join components such as fuel lines, heat exchangers, and engine parts.

CONCLUSION

Brazing is a versatile and reliable metal-joining process that, when automated, can deliver high-quality joints with enhanced efficiency and safety. The integration of robotic systems, precise heating methods, and advanced control technologies ensures consistent results and meets the demands of modern manufacturing environment.